Lathe Machine Definition , Principle Parts Of Lathe, Specification Of A Lathe Machine, Lathe Accessories

LATHE:

The lathe is a machine tool mainly used for shaping of metal. Lathe Machine is also Called as the “mother of all machines“.

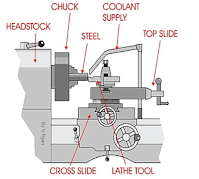

PRINCIPLE PARTS OF LATHE:

The Lathe Machine have following Main Parts:

- Bed

- Head stock

- Tail stock

- Carriage

- Saddle

- Cross Slide

- Compound rest

- Tool Post

- Apron

- Chuck

- Feed rod

- Lead Screw

- Spindle

1. Bed and Ways:

Bed is main part of the lathe made by cast iron having free graphite. The ways are the ground surface on the top side of the bed on which the carriage and tail stock ride.

(i) V-type ways.

(ii) Flat type ways.

(iii) Dovetail type ways.

2. Head Stock:

Head stock is clamped on the left hand side head stock spindle a hallow cylindrical shaft

supported by the thrust bearing. Provides a drive from work holding, live centre, face plate, chuck, driving plate. Lathe spindle are usually made having a hole or empty space inside and provided in internal taper. Spindle nose end have external screw thread. Different spindle speed on lathe is geometrical progression.

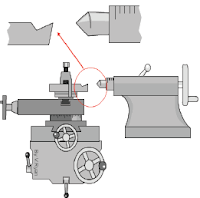

3.Tail Stock:

- Tail Stock gives support to heavy and long job.

- Use in drilling and reaming operation.

- Job is held between centre with the help of tail stock.

- Taper turning done by tail stock off set method. Turning small taper on the long work piece.

- Dead centre hardened and lubricated for reducing friction and wear.

4. Carriage & Saddle:

The carriage supports the cross-slide; compound slide, tool post moves along the ways under manual or power feed.

5. Tool post :

The tool post can hold up to four tools at once, each locked in place by hexagonal-head cap screws. Tools can be readymade carbide tipped tools of various types high speed steel tool.

6. Cross slide and compound:

The cross slide is a dovetailed slide that go in a specified direction at a right angle to the ways. The cross feed development the cutting tool into the work at a right angle to the work piece by means of a by screw and hand wheel. The compound rest assemble on top of the cross slide.

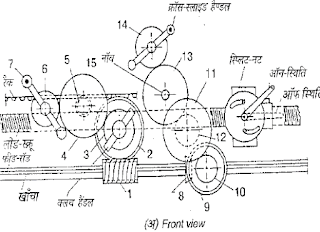

7. Apron mechanism:

To provides automatic feed to carriage. Longitudinal feed, cross feed and thread cutting low speed arrangement.

Feed Rod:

To give automatic feed to the carriage far turning operation.

Lead Screw:

Advances the carriage far thread cutting operation when half nut lever is engaged.

Lead screw of lathe acme thread (29o) andsingle start thread (Lead = Pitch).

SPECIFICATION OF A LATHE MACHINE

1. Swing Over Bed:

2. Length of Bed:

3. Distance between Centres:

4. Radius:

LATHE ACCESSORIES:

- Chucks

- Center

- Face Plate

- Mandrels

- Rests

- Driving plate

- Dogs/carrier

- Angle plate