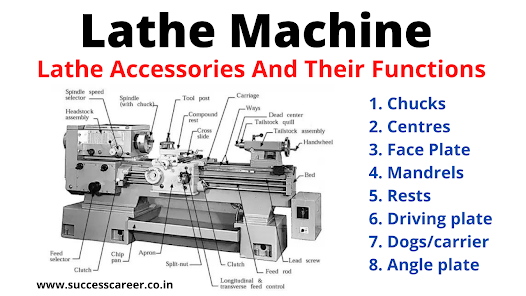

8 Different Types of Lathe Attachments & Accessories

LATHE ACCESSORIES:

5. Rests

7. Dogs/carrier

1.CHUCKS

A. Universal scroll chuck (Three-Jaw Self centering chuck):

B. Independent chuck (4-Jaw chuck)

The independent chuck has 4 jaws which at an angle of 90° to each other are moved individually on the chuck face by means of adjusting screws. This chuck can hold square, round and irregular shape of work in either a concentric or eccentric position.

Independent chuck (4-Jaw chuck)

C. Drill chuck:

The drill chuck is a small chuck which can be used in both in head stock or tail stock spindle to carry straight shank drills, reamers, tapes. The drill chuck has 3 or 4 hardened steel jaws.

D. Collet chuck:

The collet chuck is generally used to hold small work pieces in the lathe. The

collect chuck existing of a spring machine collet.

2.CENTRES

They works as solid bearings to support the work during the operation. Cast steel or high grade steel is the common material used for their manufacture. Tips made of some other materials like cemented carbide or HSS. Tip of the centre have an included angle 60 Degree.

a) There are two different types of centres i.e., live centre and dead centre.

b) A centre which assemble in the headstock spindle and rotates with the work is called live centre.

c) The centre which assemble in a tailstock spindle and does not rotate is called dead centre.

3.FACE PLATE

Face Plate is a circular cast iron disc consist a threaded hole at its centre so that it can be easily screwed to the threaded nose of the main spindle. It consists of a number of holes and slots by means of which the work can be tightened to it. Used for holding irregular shapes on lathe machine.The face plate, as shown in picture below is just like drive plate besides that it is large in diameter.

4.MANDRELS

A mandrel is a solid steel shaft or spindle which is used for holding bored parts for machining their outside surfaces on lathe. They are also known as arbors.Lathe mandrel is a cylindrical bar with centre hole at each end. Mandrel is mostly used to hold hollow work pieces or job to machined external surface.

RESTS

There are two types rests-

1. Study Rests 2. Follower Rests

1. Study Rests:

Study rests looks like a tail stock its supported work piece in the middle, as cutting tools can push (to bend or turn) the work piece away from where the centers can support them between centres on a lathe, due to its own weight it gives a springing action and carries a lot of bending moment. The result is that the turning tool is destroy very soon and may even break sometimes. To avoid this, such jobs are always supported on a device known as steady rest or centre rest.

2. Follower Rests:

A follower rest (also called a follower or a travelling steady) is similar,but it is mounted to the carriage rather than the bed.When the job is too flexible, The follow rest is assembled with lathe carriage and moves along with it to the cutting edge of the tool throughout the operation. In such cases a follower rest is used. It is assembled to the saddle of the lathe carriage and thus travels along with the tool throughout the operation.

DRIVING PLATE

It is a cast circular disc having a projected boss at its rear. There are internal threads in the boss so that it can be screwed on to the spindle nose.

DOGS OR LATHE CARRIER

They are used in combination with the driving plate. The two common forms, known as straight tail and bent tail dogs. The work to be held is inserted in the ‘v’ shaped hole of the carrier and then firmly secured in position by means of the set screws. Carriers is limited to hold a certain range of diameters only.

ANGLE PLATE

It is employed for holding work in combination with a face plate. When the shape or size of the work is irregular that it is not possible to hold the job directly on the face plate, the angle plate is used to the face plate and the workpiece hold on it. There are hole and slots are available in angle plate to clamped on a faceplate

Official YouTube Channel | Click Here |

Official Website | Click Here |

Join Official Telegram Channel | Click Here |